Rig Flooring Maintenance

Rig Flooring Maintenance is crucial for the safety, efficiency, and longevity of drilling operations on both offshore and onshore rigs.

Rig Flooring Maintenance

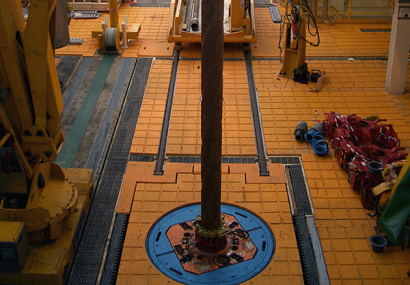

Rig flooring maintenance is a critical aspect of ensuring safety and efficiency on drilling rigs, both offshore and onshore. The drill floor is one of the most active and hazardous areas on a rig, exposed to heavy machinery, constant foot traffic, oil, mud, and harsh environmental conditions. Regular maintenance is essential to prevent slips, trips, structural damage, and equipment failure. This includes daily cleaning to remove spills and debris, routine inspections for cracks, corrosion, and loose fittings, as well as the upkeep of anti-slip surfaces to reduce the risk of accidents. Structural repairs, such as welding or panel replacement, are performed when needed to maintain the integrity of the flooring. In marine or corrosive environments, protective coatings and corrosion inhibitors are applied to prolong the life of steel components. Proper drainage maintenance is also vital to prevent fluid accumulation, which can pose both safety and environmental risks.

Why Choose Rig Flooring Maintenance?

Safety First

The rig floor is a high-risk zone where workers are constantly exposed to heavy equipment, slippery surfaces, and potential fall hazards. Regular maintenance ensures that anti-slip coatings are intact, structural integrity is preserved, and trip hazards are eliminated — significantly reducing the risk of accidents and injuries.

Operational Efficiency

A well-maintained rig floor minimizes interruptions during critical operations like drilling, casing, or tripping pipe. Damaged flooring or drainage issues can lead to unnecessary delays, which can cost thousands of dollars per hour in lost time. Maintenance helps ensure smooth, uninterrupted workflows.

Key Features:

- Thermal Comfort

- Energy Efficiency & Cost Savings

- Increased Property Value

- Improved Indoor Air Quality

- Comfort Underfoot